Contamination Control

Keep a Tight Rein on Contamination

Minimize the sludge, varnish, and organic oil degradation products that stick to and impair your machinery. Formulated with Solvancer® technology, our solutions control contamination in your turbine and compressor oils and extend the life of your machines.

You increase maintenance interval, save a significant amount of resources, and get the most out of your assets. Moreover, these treatments are part of our Fill4LifeTM sustainability initiative.

The Green and Cost-Effective Way to Control Contamination

Sustainable Solutions

Fluitec develops solutions that enable clients to reach their sustainability goals. By controlling contamination in your industrial facilities, you reduce the need to change your turbine and compressor oil.

As such, you consume fewer resources, generate less waste, reduce your demand for oil and energy, and release a smaller amount of GHGs. You reduce your environmental impact without compromising your bottom line.

No Shutdown

Unlike other contamination control technologies, Fluitec solutions don’t require shutdowns, which are costly and detrimental to productivity. Our products can be easily integrated into your system without specialized equipment or capital expense. And you enjoy measurable results — we have numerous case studies that quantify the benefits of Fluitec technologies.

DECON™

Industrial Lubricant Deposit Remover & Oil System Cleaner

Integrated with patented Solvancer® technology, DECON™ quickly dissolves varnish and organic deposits from machine internals, effectively decontaminating your material assets. It reduces the oil’s varnish potential and offers long-term protection against deposits and sludge.

Unlike other hydraulic fluid chemical products used for fluid deposits, DECON leaves no residues when it degrades.

Global manufacturers and plants trust DECON to improve operational efficiency, minimize downtime, and increase the bottom line.

DECON™ HD

Industrial Lubricant Deposit Remover & Oil System Cleaner for Heavy Duty Systems

DECON™ HD is a blend of Group IV and Group V chemistries. DECON HD is ideally suited for lubricants within the viscosity ranges of ISO 150-320 with treat rates of 6-10%.

In addition to having outstanding solubility characteristics, DECON HD also has:

- Rapid reduction of the oil’s varnish potential as measured by MPC, UC and Particle Counts.

- Excellent oxidation stability and deposit control characteristics

- No adverse impact on the in-service oil’s performance (i.e. air release, foam, demulsibility, etc.).

Vita ESP Systems

Eliminate Lube Related Shutdowns, Trips and Fail-to-Starts

The following mechanical problems lead to unscheduled shutdowns:

- Sticking and seizing valves

- Overheated bearings

- Decreased effectiveness of heat exchangers

- Increased wear on valves and other components

- Shortened life of lubricant, filters and seals

And they all have one thing in common: Varnish and Sludge

You have bigger things to worry about than free-radicals and oil degradation molecules forming and depositing in your system.

Don’t wait until you have a deposit problem which requires excessive money, time and energy to solve.

Endure IX

Removes All Acids│Fill4Life Phosphate Ester Fluid

Keep your fluid clean and dry

Filtration is a critical step in phosphate ester maintenance. Endure IX™ is a proprietary technology that removes all forms of phosphate ester degradation products. In addition to all types of acids, the absorption media removes phenolic alcohols which are responsible for varnish formation in EHC systems.

Benefits

- Removes ALL acids (stronger and weaker)

- Removes varnish forming byproducts

- Highest acid capacity

- 10x the performance of Fuller’s Earth

- 2x the performance of other IX filters

- Increases resistivity

- Removes all dissolved metals

- Longest filter life on the market

- Enables a Fill4Life™ Phosphate Ester Fluid

- Measure phenolic acid reduction with RulerV™

Stealth EHC

Dry Gas Blanketing System

Fill4Life Phosphate Ester

Keep your fluid clean and dry

Moisture is the root cause for many contamination issues in EHC systems. Because phosphate esters are hydroscopic moisture control is a critical step in phosphate ester maintenance. Stealth EHC™ uses patented technology that removes moisture from phosphate ester fluids by introducing a steady stream of clean, dry air in the reservoir. This enhances reservoir breathing systems by actively and continuously purging and dehydrating the reservoir headspace and removing water from the fluid.

Stealth EHC Benefits

- Removes dissolved moisture in oil

- Prevents the formation of condensate and rust in the oil reservoir capacity

- Eliminates the need to replace costly desiccant style breathers

- Reduces acid formation by removing water

- Minimizes the potential for particulate or water ingression through reservoir access points

- Approved by GE Energy

- Enables a Fill4Life™ Phosphate Ester Fluid

Spark Free

Prevent Electrostatic Discharge, Extend the life of your oil and filter element changes

Electrostatic Discharge Is On The Rise

Today’s advanced equipment designs are pushing lubricants with higher velocity than ever before. With a focus on cleanliness, oils are squeezing through tighter filtration. Today’s formulated products incorporating Group II and III basestocks have significantly lower conductivity values. All of these factors lead to a much greater occurrence of electrostatic spark discharge.

Sparks reach temperatures of greater than 10,000C. Antioxidant packages deplete and degradation products are produced. This translates to a shorter lubricant life and the creation of problems such as sludge and varnish. In addition, holes in the filter media are produced, significantly lowering the efficiency of the filter.

Damages Caused By Electrostatic Discharge

- Depletes additive packages

- Produces oil degradation products (Varnish)

- Damages (conventional) filter elements

Varnish Removal

Varnish is the cholesterol of the machine, and is formed in lubricating and hydraulic oils due to oxidation, stress, and other degradation mechanisms. ESP Varnish removal Technology uses specially formulated resin that removes varnish from the oil and leaves the oil clean without affecting the oil in any negative way. Consult with our experts about your varnish removal needs.

Water / Liquid Filtration

The selection of a water of liquid removal from filtration system from oil also depend on many parameters. We offer a very wide range of water/liquid filtration systems that cover nearly any industrial application. Consult our experts about your liquid/water filtration needs.....

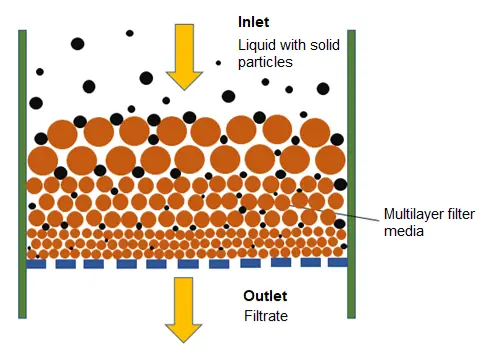

Solid Particle Filtration

The choice of a filtration system for solid particle removal depends on the type of oil, viscosity, temperature, reservoir volume, and the required cleanliness levels. Filtration units are available for nearly almost industrial oil filtration applications. Consult our experts about your filtration needs....