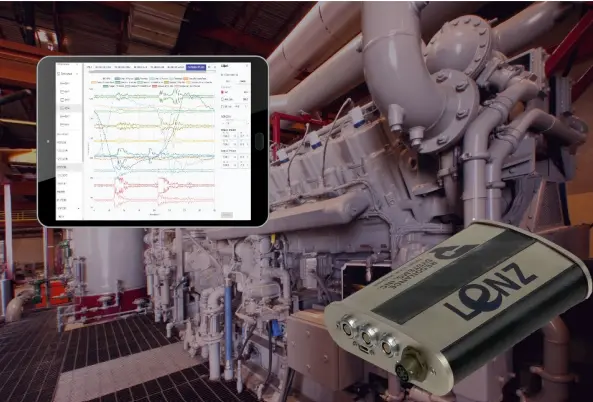

Reciprocating Compressors & Engines Monitoring

Reciprocating compressors and engines are very complicated in their design and include many components that produce very complex vibration patterns that are not possible to analyze using the traditional waveform and FFT analysis that is applied to rotating equipment.

Multi-parameter measurements (i.e. dynamic in-cylinder pressure, filtered Hi-Frequency and Low-Frequency vibration traces, ultrasound, etc.) are all measured against precise crankshaft angle. Analysis of engines (self and spark ignited) require additional measurements related to ignition. This type of analysis provides not only precise diagnosis of mechanical condition component by component but also performance (thermodynamic efficiency) evaluation. Major overhauling of reciprocating compressors and engines becomes a thing of the past saving millions of dollars and increasing production and revenues.

Various System packages are configured to meet your ultimate needs, all packages are upgradable and expandable to meet future needs:

- Portable Packages:

- Reciprocating Compressor Monitoring Kit.

- Reciprocating Engine Monitoring Kit.

- Rotating Equipment Vibration Monitoring Kit.

- Combination Kits.

- Temporary Online Packages: The system can be configures to be used for temporary installation on machines for limited periods of time then moved to another asset.

- Online (installed) Monitoring Packages:

- Reciprocating Compressor Monitoring System.

- Reciprocating Engine Monitoring System

- Rotating Equipment Monitoring System.

Read more details about products...

Contact us for more information.