Oil Analysis Laboratory

Our oil analysis is run by chemists & reliability experts who understand both the oil physical and chemical conditions as well as machinery reliability in which these oils operate. Talk to us about your needs, goals, or wishes...we shall do our best to make your targets are perfectly met and mor

Used oils analysis is a crucial element in production asset reliability program. Testing oils with the right profile of tests / parameters that show oil and machine condition is critical to making correct decisions.

NATCOM advanced oil analysis lab is equipped with a complete portfolio of analysis equipment that cover all the needed information according to world class practices.

What sets us apart is that we are:

- Independent: We are not related to any oil supplier or producer. We stand at the same distance from all.

- Reliability Experts: We are experts in industrial asset reliability, understand machines and how they operate, as well as understand oil and its characteristics and functional requirements. We have over 100 years of combined experience in machinery health, asset reliability as well as oil condition monitoring in all sorts of industries.

- Complete, comprehensive, and advanced test profile: Our lab includes the best of the breed analysis tools and systems. It is complete and comprehensive.

- Proven Track Record for over 35 years of excellent: Founded and managed by highly experienced and renown reliability professionals.

- Locally available full analysis capabilities: The only lab in Egypt that has full analysis capabilities for Turbine, and hydraulic oils.

- Very short turnaround time: We are able to provide analysis reports within 3 to 5 business days from receipt of the samples.

Equipment Oils Covered:

- Gas Turbines.

- Steam Turbines.

- Gas Compressors.

- Pumps.

- Hydraulic Controls.

- Heat Transfer Oils.

- Gearbox Oils.

- Internal Combustion Oils.

- Others.

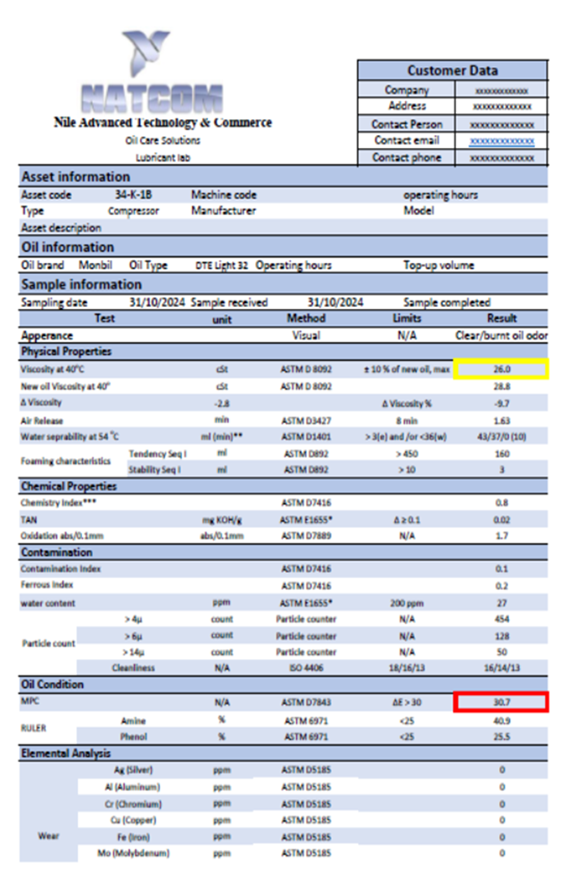

Tested Parameters:

- Viscosity

- Water Content

- Solid Particle Counting (Laser & Digital Imaging), ISO/NAS cleanliness Codes.

- Patch Filtration Testing.

- Ferrous & Non-Ferrous metals.

- WDA - Wear Debris Analysis (microscopic examination of wear particulates and mechanisms).

- K- Chemical Index dielectric permittivity.

- TDN - Tan Delta Number - Oil Life Parameter.

- TAN - Total Acid Number

- TBN Total Base Number

- Oxidation.

- Sulphation.

- Nitration.

- Soot

- Foaming Characteristics.

- Air Release Characteristics.

- Demulsibility / Water Separability.

- Elemental Analysis.

- Rust Prevention.

- Open Cup Flash Point Test.

- Copper Corrosion Test.

- MPC - MPC – Monochrome Patch Colorimetry (Varnish Potential).

- RULER – Remaining Useful Life Evaluation (antioxidant health).

Download a sample report.....

We offer a 30-day return policy for all products. Items must be in their original condition, unused, and include the receipt or proof of purchase. Refunds are processed within 5-7 business days of receiving the returned item.

Industries Served:

- Power Generation.

- Oil & Gas (upstream, midstream, and downstream).

- Chemicals & Fertilizers.

- Petrochemicals.

- Air Separation / Industrial Gases.

- Others.

We offer a 30-day return policy for all products. Items must be in their original condition, unused, and include the receipt or proof of purchase. Refunds are processed within 5-7 business days of receiving the returned item.

Contact us

Fill in the below form and our professional engineers will call you as soon as possible to discuss your needs and provide you with the solution