Machinery Vibration Monitoring

AMS 2140 Machinery Health Analyzer product family

The world's best and most desired portable machinery analyzer and a route-based data collector. It comes in 1, 2, and 4 channel versions with vast capabilities that are selected and configured according to the specific need of each and every operation. It offers unmatched ease of use, capabilities, and flexibility.......

Discover more

AMS 2600 Machinery Health Expert

The AMS 2600 Machinery Health Expert satisfies the need between two-channel portable analyzers and permanently-installed online vibration monitoring. Before a planned outage, connect all 24 channels of the AMS 2600 to simultaneously record continuous time waveforms. Whether diagnosing a suspected load, speed, or batch dependent problem, bringing a new machine online, or verifying critical speed prior to machine acceptance from vendor, the AMS 2600 has the power to deliver quantitative answers.

AMS Wireless Vibration Monitor

The AMS Wireless Vibration Monitor delivers full vibration data over a self-organizing wireless mesh network. It provides rich information about machinery health for both operations and maintenance personnel. Overall vibration, PeakVue measurements and temperature readings can be easily integrated into any control system or plant historian, while diagnostic data can be displayed by AMS Device Manager and AMS Machine Works software with alert broadcast via the AMS Optics asset performance platform.

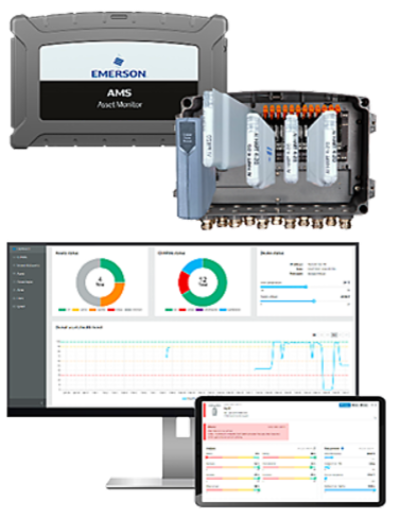

AMS Asset Monitor

AMS Asset Monitor manages pervasive sensing while providing prediction, protection and edge process monitoring capabilities, mounting at the asset to reduce cabling requirements and installation costs. It accommodates up to 12 CHARMs including Vibration CHARMs as well as DeltaV CHARMs for process inputs.

AMS Asset Monitor features powerful out-of-the-box software functionality via web browser for analysis, reporting, and alerting. This web-based thin client interface features an internal Logic Studio with pre-programmed application solutions for easy-to-understand analysis and alert reporting, and its Asset Studio interface delivers asset information to the user’s mobile device or desktop thin client.

AMS 6500 ATG Online Protection System

The AMS 6500 ATG protection system is a modern protection-plus-prediction system designed to easily replace obsolete protection systems, allowing users to cost-effectively initiate online prediction monitoring of critical rotating machinery assets like steam turbine generators, gas turbines, boiler feed pumps, offshore compressors, pipeline turbo compressors, chemical industry compressors, turbo exhausters, blowers, boosters and more.

AMS 6500 ATG includes flexible cards that can be configured to acquire prediction data, an embedded OPC server, and a mobile app for viewing data from anywhere on the plant network.

Although no additional software is required when using AMS 6500 ATG, reliability, operations, and maintenance personnel can move beyond simple fault recognition and take analysis a step further by pairing with AMS Machine Works as a complimentary solution.

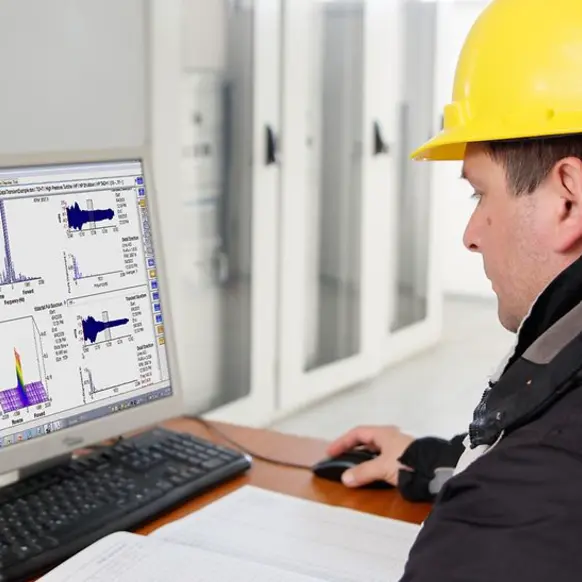

AMS Machinery Manager Software

AMS Machinery Manager integrates multiple predictive maintenance techniques with comprehensive analysis tools to provide easy and accurate assessment of the machinery health across different types of mechanical assets in your facility. The modular technology applications incorporate diagnostic and reporting sources into a common database for analysis of machinery health across the entire plant. New software releases are available at no charge to customers via AMS Machinery Manager product support, delivered through Guardian.

ِAMS Machine Works

You collect data from many rotating machines—from balance-of-plant assets like pumps, motors, gear boxes, and fans, to higher consequence assets like turbines, generators and compressors—but having a single location where the data comes together to identify bad actors quickly would be more efficient.

Asset management for industrial machinery is simplified in AMS Machine Works software, where users can quickly begin identifying potential equipment issues with their monitored machinery. AMS Machine Works combines predictive maintenance techniques with comprehensive, patented analysis tools to provide easy and accurate assessment of machinery health. This award-winning software ingresses measurement from compatible AMS machinery health data acquisition technology like AMS Wireless Vibration Monitor, AMS Asset Monitor, AMS 6500 ATG, and others. Read more......

Sensors & Sensor Hardware

Accelerometers, Velometers, Displacement Sensors, 4-20 mA Transmitters, Vibration Switches, Modal Impact Hammers, Magnets and sensor mounting accessories, Signal Conditioners, enclosures, junction and termination boxes.

Portable Vibration Calibration

Laboratory quality, accuracy, and capability portable vibration calibrators.

Dynamic Pressure Sensor Calibration Systems