Vibration Monitoring Systems

Machinery Vibration analysis is a very powerful tool to assess the mechanical health of an asset. Vibration is a mechanical energy produced by the machine due to malfunctions, it is a wasted energy (losses) that causes machine health degradation. Other forms of losses caused by malfunctions or imperfections of the machine are noise, and heat. The vibration signal measured on rotating machinery contains a huge amount of information about the machine health condition. Vibration signal is utilized in many different ways to monitor and protect machines as well as perform diagnostics to find the root cause of the problem and define the action needed to be applied to resolve it.

Vibration is measured and analyzed to assess and monitor the health of industrial rotating machinery in various scenarios:

- Portable measurements: using portable handheld devices such as overall meters, or analyzers that are carried by an engineer or technician and moved from one point on a machine to another and from one machine to another to measure the levels either to compare to certain industry standards or do some detail diagnostics to find the root cause and fix it.

- Online / permanently installed on an important asset and connected to some sort of a display either locally beside the asset or via long cables to the control room where an operator is able to see the instantaneous level and trend, and incase of exceeding alarm or a preset level, the system takes an action and may even in some cases shut down the machine, hopefully before destructive damage or catastrophic failure. on critical assets that has high impact on production, such signals can be analyzed online in real time to provide early information about developing abnormalities so that actions can be taken early enough before it causes production losses.

Portable Vibration Devices - Overall Vibration Meters

Overall vibration meters are simple devices that are used as a first level of information about the general condition of the machine as compared to known ranges defined either by the equipment manufacturer, reliability team of the organization, industrial standards, and common industry practices. These measurements cannot be used for making a final decision as to what action to be taken, detailed analysis of the machine vibration must be performed to identify the root cause of vibration. These devices are typically used by technicians and shift personnel to get a first hand indication about the mechanical health of the machine.

Contact us for further information

Portable Vibration Analyzers

Singe and multi- channel analyzers that are used to collect detailed vibration information from a large number of machinery in routine data collection basis. These analyzers collect data based on predefined instructions that are downloaded from a PC-based software. Data collected in the field are uploaded back to the software for trending and analysis. Field based analysis capabilities help the person collecting the data to perform advanced analysis in case a field alarm is triggered bringing back enough information for analysis at the office.

Installed Sensors - Overall Level Monitoring

Accelerometers, Velometers, and Absolute Displacement sensors are installed on some machines (fans, motors, etc.) to provide simple, cost effective permanent monitoring soliton. These come in different scenarios and configurations such as dynamic signal output sensors, 4-20 mA transmitters, Switches, and local monitors. Depending on the selection and configurations, some of these installations provice both local protection, connectivity to SCADA systems, PLCs, or DCSs as well as enable dynamic signal output for analysis by portable analysis equipment such as analyzers used for data collection.

Contact us for further information

4-20 mA Vibration Transmitters

These transmitters have small foot print and are typically installed on important assets and send signals via a simple twisted-pair cable to provide instantaneous monitoring and trending of the vibration levels to SCADA Systems, PLCs, DSCSs. which are typically monitored in the control room by an operator.

Online / Installed Systems - Switches

Vibration Switches are single-Point protection monitors that are pre-configured and set to certain high and high-high levels for alarming and shutdown via local circuitry. These switches have various capabilities and come in several forms and shapes depending on the application and the choice of the designer or the instrumentation engineers. These are Mechanical Switches, Electronic Switches, Programable Smart Switches.

Online / Installed Systems - Protection Monitors

Online Protection Monitoring Systems use multiple sensors installed on selected locations on the monitored equipment and are able of displaying instantaneous values as well as making decision according to a preset protocol relating signals from various sensors. Typically these monitors can provide dynamic signal output to be analyzed by either portable vibration analyzers or multichannel analysis and prediction monitoring systems.

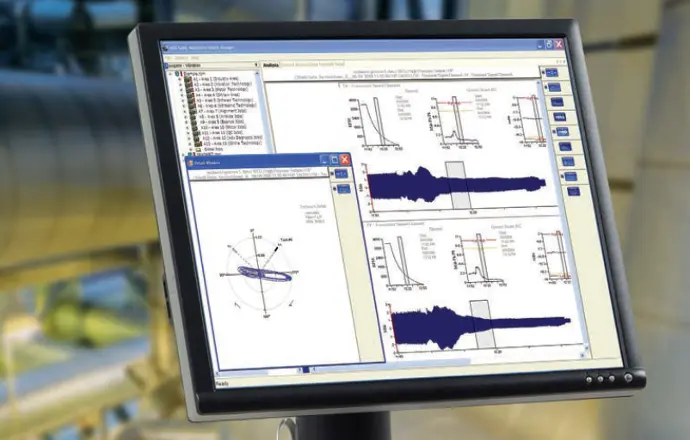

Online / Installed Systems - Prediction Monitors

These are typically multi-channel online systems with extensive analysis and monitoring capabilities. These are typically installed to monitor production equipment that are critical to the operation where early detection and diagnosis of the root cause is necessary so that decisions can be made early enough to prevent the development.

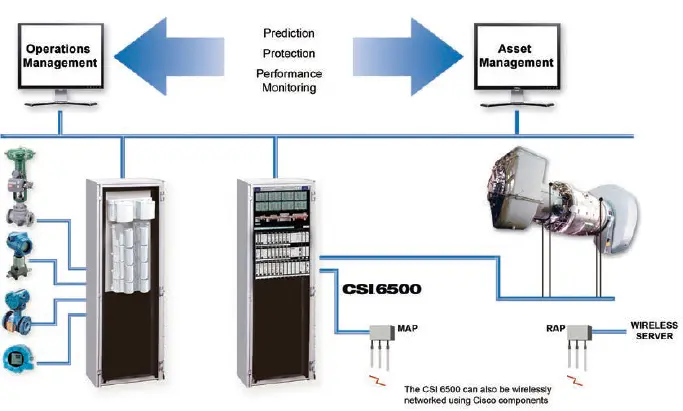

Online / Installed Systems - Combined Protection & Prediction

These top of the line condition monitoring systems include both protection and prediction functions and are typically installed on the most critical assets requiring the highest level of reliability.

Contact us for further information

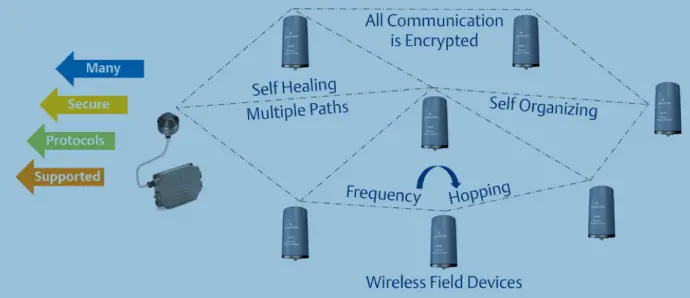

Online / Installed Systems - Wireless Sensors with Cloud Connectivity - IOT

Wireless monitoring offers specific advantages that make them useful in some applications within a plant. These sensors provide around the clock monitoring of semi critical assets that are spaced around the plant, in remote locations, dangerous or difficult to reach. Wireless monitoring also save cabling cost. The use of wireless compliments all other monitoring techniques and help reduce the cost or routine data collection based monitoring.

Contact us for further information

Vibration Sensors & Systems Calibration

Sensor calibration is critical to ensuring the precision of the measured signals. All types of vibration sensors can be calibrated at a calibration lab but can also be checked and calibrated in the field using portable calibrators. PVC - Portable Vibration Calibrator brings lab precision to the field in a portable battery operated tool that can be used by the instrumentation and condition monitoring engineers.

Vibration & Modal Testing

Study of the vibration behavior of products during the development and pre-manufacturing testing stage is a crucial testing procedure to make sure the final product is well designed and is able to stand the operating condition in which is is designed to work. These range from very small components such as printed circuit boards, passenger cars, trains, civil and military aircrafts and missiles, space shuttles, satellites, etc. These are also important tools in research and development labs, in universities and product development departments in industries.