Oil Filtration

The Contamination Problem

Hydraulic fluid and lubricating fluids become polluted with use; a build-up of varnish, siloxane, salts, particulates and water causes equipment wear, reduces efficiency and risks breakdown. Typically, this is resolved by regular fluid changes and routine maintenance. This is expensive, often awkward and polluting.

Heavy fuel oils contain similar pollutants which can contaminate and wear the fuel system. These are burnt off in the combustion cycle, resulting in smoke and particulate emissions, particularly at start-up.

Nano Filtration

The patented nano filtration technology removes water, siloxane, varnish, particulates and salts from hydraulic oil, lubricating oil and fuel oil down to 0.1 Micron particle size. Well below ISO 4406 (ASTMD975) limits.

Reduced Maintenance

Installed in a correctly designed offline filtration system, Delta-Xero filter cartridges reduce operating fluid and fuel oil pollutants to very low levels. Significantly extending operating fluid life, reducing maintenance requirements, extending equipment life and helping fuel oils burn more cleanly.

Commercial Benefits

Nano fluid conditioning systems extend fluid life, reduce maintenance requirements, extend equipment/component life significantly, and improve overall system efficiency and reliability by up to 80%. Taken together these save time, consumables and achieve significant reductions in cost. Fluid conditioning results in longer operating fluid and equipment life and lower operating costs.

Lower Environmental Impact

Fewer operating fluid changes reduce the need to dispose of used hydraulic fluid and lubrication oil. Reduced equipment maintenance reduces system downtime and reduces the need to work on equipment in difficult or polluted environments such as wind turbines, power generation and waste processing.

NATCOM Oil Filtration Offering

NATCOM offers the most comprehensive, efficient, and economic oil filtration systems on the market today through partnership with both Filtertechnik Ltd (UK) and Delta-Xero Ltd (UK). The selection of which filtration system that perfectly fits your application needs is at the heart of our engineering team.

Delta-Xero Oil Filtration

Delta-Xero manufactures offline fluid conditioning systems for hydraulic, lubrication, fuel and other operating fluids used in energy, construction, marine, waste management and manufacturing.

Delta-Xero patented nano filtration technology removes water, siloxane, varnish, particulates and salts from hydraulic oil, lubricating oil and fuel oil down to 0.1 Micron particle size, well below ISO 4406 (ASTMD975) limits.

Filtertechnik Oil Filtration

Filtertechnik offers a comprehensive range of oil filtration systems that fit nearly every application needs. Through partnership with Schroeder Filtration Systems (USA), we deliver filter elements for hydraulic, lubrication, fuel, coolant and process filters from diesel fuel through to heavy gear oils. We can also provide both originals and alternatives for Hydac, Pall, Baldwin, Parker, UCC, EPE, Mahle, MP Filtri, Stauff, Internormen and Donaldson amongst many others, all at competitive prices. Contact us for further information... or Download Filtertechnik Catalogue or visit Filtertechnik website for details

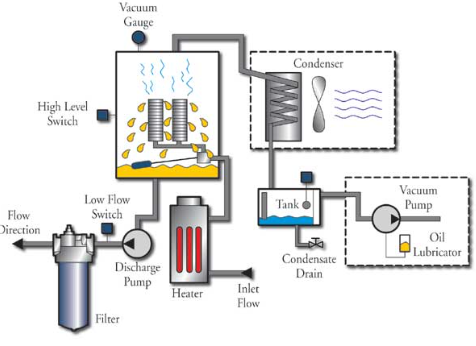

Low Vacuum Dehydration

Water is one of the most damaging contaminants that can migrate into a hydraulic or lubrication system. It can cause catastrophic failures, accelerated wear, part corrosion, and oil viscosity and lubricity degradation.

whether you need a mobile low vacuum dehydration skid, fixed dehydration unit, Water Removal Media, or Dry Nitrogen dehydration system for tank blanketing, we have the proper solution for you.