World Class Products

Machinery Engineering Services

NATCOM's allies and principals who are global leaders in plant rotating equipment and production assets are capable of re-engineering processes, equipment and controls to improve their performance, throughput, and efficiency based in-depth engineering studies is a specialty service.

Read more...

Asset Reliability Consulting Services

To help our clients solve difficult problems and maximize the utilization of reliability technologies with the purpose of maximizing their production, minimizing waste and energy consumption, reduce cost of goods sold, and minimize carbon foot print to save our environment, we offer high level consulting service.

Read more...

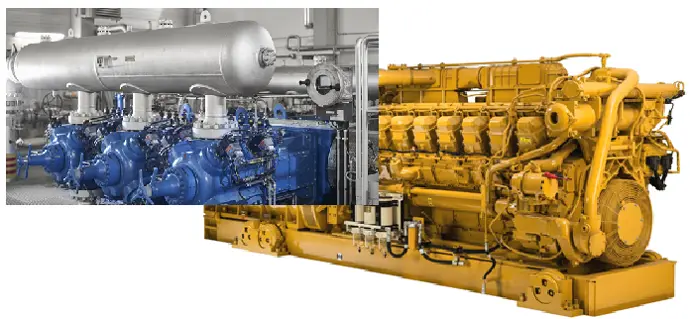

Engineered Services for Rotating Equipment

Maintenance and repair of rotating machinery (electric motors, pumps, gearboxes , industrial fans , blowers ...), and turbomachinery ( centrifugal compressors, Axial Flow Compressors, Turboexpanders, reciprocating compressors and steam turbine ).

Read more...

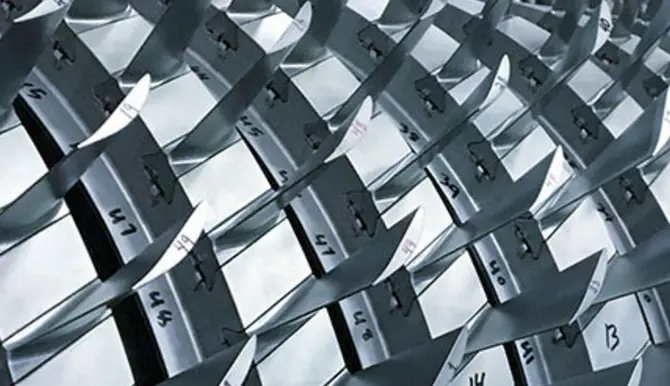

Rotating Machinery & Parts, and Engineered Solutions

Axial Compressors, Centrifugal Compressors, FCC Expanders, Gas Turbines, Nitric Acid Expanders, Oil Free Screw Compressors, Power Turbines, Steam Turbines, Reciprocating Compressors, Blade Manufacturing, Technology Services, Machining,

Read more...

Turboexpanders, Engineered Parts & Services

NATCOM is the local business partner of LA Turbine (A Chart's company). LA turbines can not only provide new turboexpanders specially designed to meet the most stringent energy and process requirements but also provide a full set of engineered spares and replacement parts that are as good as the OEM's (of any competitive brand) or even improved...

Technology & Product Training

Training is vital to the success in the application and use of any product. To ensure the ultimate success of our customers and help them reap the full potential and benefit of the products they purchase from us we spare no effort to provide the best training both on the products and on the technologies behind them.

Turbomachinery Control Solutions

NATCOM is the local business partner of CCC - Compressor Controls Corporation (a Honeywell company) who is the global leader in the technology of turbomachinery controls. Whether you are planning to add a new compressor or a turbine to your production facility, or wish to upgrade an old one, talk to us and we will prove to you how we can help you make the best out of your investment and protect your assets and profits. For further information, click here...

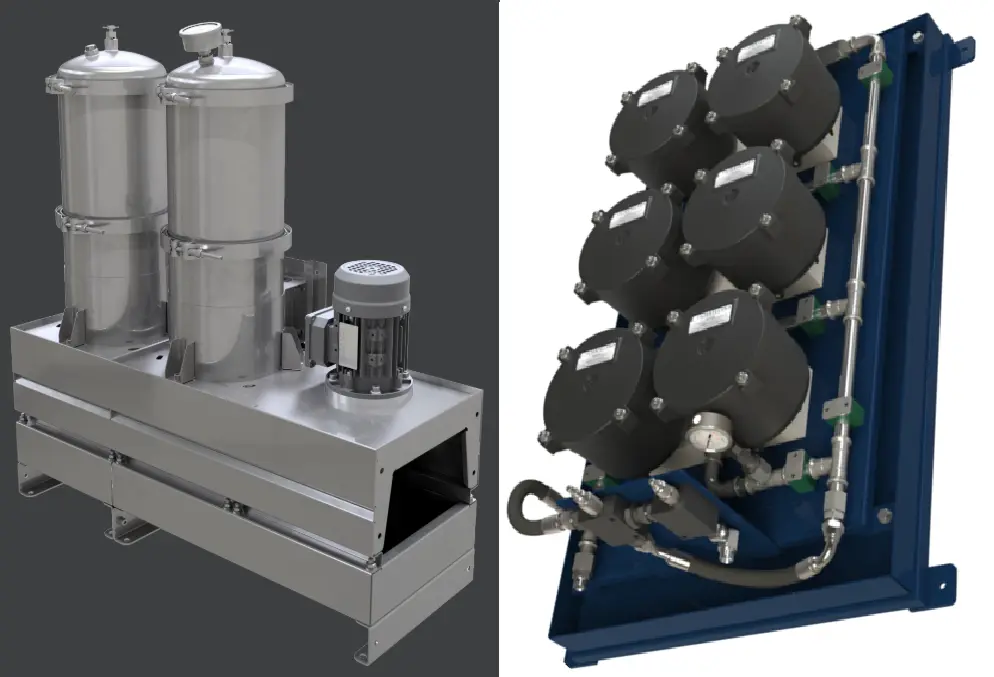

Machinery Protection & Prediction Monitoring

Machines that are critical to the operation such as compressors an turbines must be closely monitored in a detailed way in order to make sure developing operational and health problems are identified early and accurately enough so that the proper decision and action is made in time before the process or production is affected. Visit our principals Emerson Automation Solutions for more details.

Infrared Thermal Imaging

Heat is emitted from objects in a specific range of waveform in the light spectrum (Infrared). The use of Infrared Thermography is a profound tool in electrical inspection, mechanical predictive maintenance, Static equipment inspection, energy conservation, as well as in operational efficiency and reliability.

Field Balancing

Field Balancing of critical rotating equipment such as Fans, Blowers, etc. that are widely used in many industries such as Cement, Steel, Food Processing, Chemical and Fertilizers, mining, etc. is necessary element in the asset reliability matrix. Balancing these rotors to precision levels in the field save lots of time, effort, and downtime, helping improve productivity and profitability.

Motor Current Signature Analysis - MCSA

Precision Machinery Alignment

The higher the precision of aligned shafts the longer the machine will live and the less power it consumes. Precision alignment of machine components is crucial to reliability and profitability.

Vibration Monitoring

Vibration Analysis provides a wealth of information about the mechanical health of rotating equipment used in industrial operations. Vibration monitoring can be performed on permanent installation typically on critical assets and by routine data collection using portable analyzers on less critical equipment. Read more...